Mastering Your CHEP Audit: A Guide To Efficiency & Savings

In the intricate world of global supply chains, efficiency, sustainability, and cost control are paramount. Businesses across various sectors, from consumer goods to manufacturing, rely on robust logistics to deliver products seamlessly. At the heart of many of these operations lies CHEP, the global leader in sustainably moving goods, providing reusable pallets and containers that optimize over 300,000 supply chains throughout the world. While CHEP's share-and-reuse model offers significant advantages, effectively managing these assets, particularly through a comprehensive CHEP audit, is crucial for financial health and operational excellence.

A CHEP audit isn't merely a procedural formality; it's a critical exercise in accountability and optimization. It ensures that your company's records align with CHEP's, helping to prevent costly discrepancies, improve inventory accuracy, and enhance overall supply chain visibility. This article will delve deep into the world of CHEP audits, offering practical insights, best practices, and strategic advice to help your business navigate these essential processes with confidence and achieve greater efficiency and savings.

Table of Contents

- What is CHEP and Why Does It Matter?

- Understanding the CHEP Audit: What It Entails

- The Importance of a Robust CHEP Audit Strategy

- Preparing for Your CHEP Audit: Best Practices

- Common Challenges in CHEP Audits and How to Overcome Them

- The Role of Technology in Streamlining CHEP Audits

- Beyond Compliance: Strategic Benefits of a Proactive CHEP Audit

- Partnering with CHEP for Audit Success

What is CHEP and Why Does It Matter?

Before diving into the specifics of a CHEP audit, it's essential to grasp the fundamental role CHEP plays in the global supply chain. CHEP is a global provider of supply chain solutions, serving the consumer goods, fresh food, beverage, manufacturing, and retail sectors in more than 60 countries. As a Brambles company, the CHEP purpose is to connect people with life’s essentials every day. They achieve this by managing the world’s largest pool of reusable pallets and containers.

The core of CHEP's business model is its circular 'share and reuse' system. Instead of businesses purchasing and managing their own pallets, which often leads to significant waste, CHEP offers a rental service. This model promotes the shared use of their platforms among supply chain participants, significantly reducing environmental impact and operational costs for individual companies. Through this share and reuse model, CHEP moves more goods to more people in more places than traditional methods allow. Their range of CHEP pallets and containers can maximize your supply chain efficiency, supported by their unmatched global network of CHEP pallet locations. This extensive network and commitment to sustainability make CHEP a vital partner for businesses aiming for greater efficiency, sustainability, and circularity in their operations.

Understanding the CHEP Audit: What It Entails

A CHEP audit is a systematic review and reconciliation process designed to verify the accuracy of a client's CHEP account records against the physical inventory of CHEP assets (pallets and containers) on their premises. Essentially, it's a stocktake and a data verification exercise rolled into one, with the aim of ensuring that both CHEP and the client have an identical understanding of how many CHEP assets are in the client's possession and where they are located within their supply chain.

During a typical CHEP audit, a CHEP representative or an authorized third-party auditor will visit your facility. They will:

- Review Documentation: Examine your internal records, such as receiving logs, shipping documents, transfer records, and any other paperwork related to CHEP pallet movements.

- Conduct Physical Count: Perform a physical count of all CHEP pallets and containers present at your site. This includes assets in storage, those actively being loaded or unloaded, and any damaged units awaiting collection.

- Reconcile Data: Compare the physical count with your documented records and CHEP's own system records. The goal is to identify any discrepancies – whether overages or shortages.

- Identify Causes of Discrepancies: Work with your team to understand why any differences exist. This might involve investigating missing transfer documents, incorrect data entry, or unrecorded movements.

- Propose Adjustments: Based on the reconciliation, adjustments may be made to your CHEP account to reflect the true physical inventory. This can sometimes result in charges for lost or unaccounted-for equipment.

The Importance of a Robust CHEP Audit Strategy

For any business utilizing CHEP's services, developing and executing a robust CHEP audit strategy is not just about compliance; it's a critical component of financial prudence and operational efficiency. Neglecting this aspect can lead to significant financial penalties, operational bottlenecks, and a lack of control over a vital part of your supply chain. This is where the principles of YMYL (Your Money or Your Life) come into play, as inaccurate CHEP management directly impacts a company's financial health.

Minimizing Discrepancies and Fees

One of the most immediate and tangible benefits of a proactive CHEP audit strategy is the reduction of unexpected costs. CHEP charges for lost or unreturned equipment. If your internal records don't accurately reflect the pallets and containers you have, you could be billed for equipment you no longer possess or for discrepancies that could have been resolved. These charges can accumulate quickly, impacting your bottom line significantly. A thorough audit process helps to:

- Prevent Unnecessary Charges: By identifying and rectifying discrepancies before they become official charges, you can avoid paying for lost or damaged equipment that was never truly lost or was damaged through normal wear and tear within the agreed terms.

- Optimize Equipment Utilization: Understanding exactly how many pallets you have and where they are helps you avoid ordering more than you need, reducing rental fees and improving efficiency.

- Improve Billing Accuracy: Regular audits ensure that your invoices from CHEP accurately reflect your usage, eliminating disputes and streamlining financial reconciliation.

Enhancing Supply Chain Visibility

Beyond the financial implications, a strong CHEP audit strategy significantly enhances your overall supply chain visibility. Knowing precisely where your CHEP assets are at any given time is invaluable for operational planning and execution.

- Improved Inventory Management: Accurate counts of CHEP pallets contribute to better inventory management for your own products, as you have a clearer picture of available packaging materials.

- Streamlined Operations: When you know your pallet availability, you can better plan shipments, reduce loading/unloading delays, and optimize warehouse space.

- Data-Driven Decision Making: Consistent audit data provides insights into your pallet flow, identifying bottlenecks or inefficiencies in your internal processes or with your trading partners. This data can inform strategic decisions about warehouse layout, transportation routes, and partner collaboration.

Preparing for Your CHEP Audit: Best Practices

Effective preparation is the cornerstone of a successful CHEP audit. A well-prepared team can minimize disruption, ensure accuracy, and ultimately save the company time and money. Here are some best practices to consider:

Leveraging MyCHEP for Data Management

In today's digital age, manual tracking alone is insufficient. CHEP provides powerful tools to assist its partners, and MyCHEP is undoubtedly one of the most critical. Mychep is an online portal for managing CHEP accounts, placing orders, and tracking deliveries efficiently. More comprehensively, Mychep is an online portal for managing CHEP accounts, orders, invoices, and data related to pallets and containers. This platform is designed to be your primary resource for all CHEP-related transactions and data. To maximize its utility for audit preparation:

- Regular Data Entry: Ensure all incoming and outgoing CHEP pallet movements are recorded accurately and promptly in MyCHEP. This includes receipts from CHEP, dispatches to customers, and transfers between your own facilities.

- Invoice Reconciliation: Regularly cross-reference your internal records with invoices and statements from MyCHEP. Discrepancies identified early are much easier to resolve.

- Utilize Reporting Features: MyCHEP offers various reports that can provide a real-time snapshot of your account balance and transaction history. Use these reports to conduct internal mini-audits and identify potential issues before an official CHEP audit.

- Train Your Team: Ensure all relevant personnel – from receiving and shipping clerks to inventory managers – are proficient in using MyCHEP and understand the importance of accurate data entry.

Physical Inventory and Reconciliation

While digital records are vital, they must always be backed by physical reality. A robust preparation strategy includes regular physical inventory counts and reconciliation processes:

- Scheduled Internal Counts: Implement a schedule for conducting your own physical counts of CHEP pallets and containers. This could be weekly, monthly, or quarterly, depending on your volume and operational complexity.

- Dedicated Storage Areas: Designate specific, organized areas for CHEP pallets – received, dispatched, damaged, and awaiting collection. This makes physical counting much easier and reduces the chance of misplacement.

- Damage Reporting: Establish a clear process for identifying and reporting damaged CHEP equipment. Damaged pallets often need to be accounted for separately and may be subject to different handling procedures or charges.

- Reconciliation Protocol: After each internal physical count, compare it with your MyCHEP records. Investigate any discrepancies immediately. This iterative process helps to catch errors early and maintain a high level of accuracy in your CHEP account.

- Pre-Audit Walkthrough: Before the official CHEP audit, conduct a comprehensive walkthrough of your facility with your team. Ensure all CHEP assets are accessible, organized, and accounted for. This helps identify any last-minute issues and ensures a smooth audit process.

Common Challenges in CHEP Audits and How to Overcome Them

Even with the best preparation, businesses can encounter challenges during a CHEP audit. Understanding these common pitfalls and having strategies to overcome them is key to a smooth and successful audit outcome.

- Data Discrepancies: This is arguably the most common challenge. It arises from errors in data entry, unrecorded movements, or miscommunication between departments or with trading partners.

- Overcome: Implement stringent data entry protocols. Use automated systems where possible. Conduct frequent internal reconciliations between physical counts and MyCHEP records. Establish clear communication channels with trading partners regarding pallet transfers.

- Unaccounted for Pallets: Pallets can go missing due to theft, damage beyond repair, or simply being misplaced within a large facility or at a trading partner's site.

- Overcome: Enhance physical security measures. Implement clear procedures for handling damaged equipment. Conduct regular, thorough physical counts. Consider tracking technologies for high-value or high-volume movements.

- Lack of Dedicated Personnel/Training: If staff responsible for CHEP management are untrained or spread too thin, errors are inevitable.

- Overcome: Designate specific individuals or teams responsible for CHEP management. Provide comprehensive training on MyCHEP, internal procedures, and the importance of accuracy. Foster a culture of accountability regarding CHEP assets.

- Seasonal Fluctuations and High Volumes: Businesses with highly seasonal demand or extremely high volumes of pallet movements can find it challenging to maintain accurate counts.

- Overcome: Plan for increased staffing or automation during peak seasons. Implement more frequent mini-audits during high-volume periods. Consider dedicated staging areas for CHEP pallets to manage flow.

- Communication Gaps with Trading Partners: Pallets often move between multiple parties in a supply chain, and if transfer documentation isn't consistent or timely, discrepancies can arise.

- Overcome: Establish clear, written agreements with trading partners regarding CHEP pallet transfers. Implement standardized documentation for all movements. Regularly reconcile transfer data with partners.

The Role of Technology in Streamlining CHEP Audits

In an increasingly digitized world, technology plays a pivotal role in transforming what was once a labor-intensive and error-prone CHEP audit process into a streamlined, accurate, and efficient operation. Beyond MyCHEP, which is foundational, other technological advancements can significantly enhance your audit readiness and overall CHEP management.

- Warehouse Management Systems (WMS): Modern WMS can be integrated to track the movement of CHEP pallets alongside your own inventory. By scanning pallets upon receipt and dispatch, the WMS can automatically update your internal CHEP records, reducing manual data entry errors and providing real-time visibility. This integration can also generate reports specifically for CHEP pallet movements, making reconciliation much simpler.

- Automated Data Capture (Barcode/RFID): Implementing barcode scanning or, for more advanced operations, RFID (Radio-Frequency Identification) technology can revolutionize accuracy. Instead of manual counts, scanners can quickly and accurately capture pallet IDs, drastically reducing human error and speeding up the physical inventory process. RFID, in particular, allows for rapid, line-of-sight independent scanning of multiple pallets simultaneously.

- Electronic Data Interchange (EDI): For high-volume users, setting up EDI with CHEP and key trading partners can automate the exchange of transaction data. This means that when pallets are shipped or received, the data is automatically transmitted between systems, minimizing manual intervention and ensuring that both parties' records are updated simultaneously, reducing the likelihood of discrepancies.

- Analytics and Reporting Tools: Leveraging business intelligence (BI) tools can help you analyze your CHEP data more effectively. These tools can identify trends in pallet movements, highlight potential loss points, forecast future pallet needs, and provide dashboards that give an instant overview of your CHEP account health. Proactive analysis can pinpoint issues before they escalate into significant audit problems.

- IoT and Telematics: While perhaps more advanced, Internet of Things (IoT) sensors and telematics devices can be attached to pallets or vehicles to track their location and movement in real-time. This level of granular tracking can provide irrefutable evidence of pallet movements, which can be invaluable in resolving disputes during a CHEP audit and optimizing logistics.

Beyond Compliance: Strategic Benefits of a Proactive CHEP Audit

While avoiding fees and ensuring accurate billing are primary drivers for a CHEP audit, the strategic advantages extend far beyond mere compliance. A proactive approach to CHEP asset management, underpinned by regular and thorough audits, can unlock significant long-term benefits for your business, aligning with broader goals of operational excellence and sustainability.

- Enhanced Supplier and Customer Relationships: By maintaining accurate CHEP records and efficiently managing pallet flows, you demonstrate reliability and professionalism to your trading partners. This fosters stronger, more collaborative relationships, as disputes over pallet balances are minimized, and trust is built. A smooth pallet exchange process contributes to overall supply chain harmony.

- Optimized Logistics and Reduced Carbon Footprint: Understanding your precise pallet needs and movements allows for better logistics planning. You can optimize transportation routes, reduce empty runs, and ensure that pallets are returned to CHEP depots efficiently. This not only saves on transportation costs but also contributes to a reduced carbon footprint, aligning with corporate sustainability initiatives. CHEP itself promotes the shared use of their platforms among supply chain participants under a circular ‘share and reuse’ model, and your efficient management complements this.

- Improved Internal Processes and Employee Accountability: The discipline required for a successful CHEP audit encourages the establishment of clear internal procedures for handling, tracking, and reporting pallet movements. This process improvement leads to greater employee accountability and a more organized warehouse environment. When employees understand the financial and operational impact of accurate pallet management, they are more likely to adhere to best practices.

- Data-Driven Strategic Planning: The rich data gathered through consistent CHEP management and audit processes can be a goldmine for strategic planning. You can identify peak usage periods, analyze pallet turnaround times, and forecast future demand more accurately. This data can inform decisions on warehouse expansion, equipment procurement, and even new market entries, providing a competitive edge.

- Contribution to Circular Economy Principles: By actively participating in CHEP's share and reuse model and ensuring efficient asset utilization, your company directly contributes to the principles of the circular economy. This commitment to sustainability can enhance your brand reputation, appeal to environmentally conscious consumers, and potentially open doors to new business opportunities. CHEP is the global leader in sustainably moving goods, and your proactive audit efforts reinforce this shared vision.

Partnering with CHEP for Audit Success

A CHEP audit should not be viewed as an adversarial process, but rather as a collaborative effort to ensure the integrity of the shared asset pool and the accuracy of your account. CHEP's success is intrinsically linked to the efficient management of its reusable assets, and they are committed to helping their partners achieve this. They believe that learning how working with CHEP is easy, and this extends to the audit process.

- Open Communication: Maintain open and honest communication with your CHEP account manager. If you anticipate challenges or have questions about your account, reach out proactively. They can often provide guidance, resources, or even extend deadlines if necessary.

- Utilize CHEP Resources: CHEP offers various resources to support its clients, including online tutorials for MyCHEP, best practice guides, and customer support. Make use of these tools to educate your team and streamline your processes.

- Understand Your Contract: Thoroughly understand the terms and conditions of your agreement with CHEP, especially regarding asset responsibility, damage policies, and audit procedures. Clarity on these points can prevent misunderstandings.

- Feedback and Improvement: After an audit, take the opportunity to discuss the findings with CHEP. Understand their recommendations for improvement and provide your own feedback on the process. This dialogue can lead to mutually beneficial adjustments in procedures.

- Strategic Partnership: Recognize that CHEP aims to be a strategic partner for greater efficiency, sustainability, and circularity. By working together, you can optimize your supply chain, reduce costs, and contribute to a more sustainable logistics ecosystem. With their CHEP pallet locations and unmatched global network, discovering how to leverage this partnership for audit success is key.

Conclusion

The CHEP audit is more than just a check-up; it's a vital component of effective supply chain management. From understanding CHEP's global share-and-reuse model to meticulously preparing your records and physical inventory, every step contributes to financial accuracy and operational efficiency. We've explored how a robust audit strategy can minimize costly discrepancies, enhance supply chain visibility, and how leveraging tools like MyCHEP and other technologies can streamline the entire process.

Beyond mere compliance, a proactive approach to your CHEP audit offers strategic benefits, fostering stronger relationships with partners, optimizing logistics, and championing sustainability. By viewing CHEP as a collaborative partner and utilizing their extensive resources, businesses can navigate audits with confidence, ensuring not only financial integrity but also contributing to a more efficient and sustainable global supply chain. Take control of your CHEP account today. We encourage you to review your current CHEP management practices, implement the best practices outlined, and reach out to CHEP for further support. Share your experiences or questions in the comments below – your insights can help others on their journey to mastering the CHEP audit!

Chep Case Study - Expression for Growth

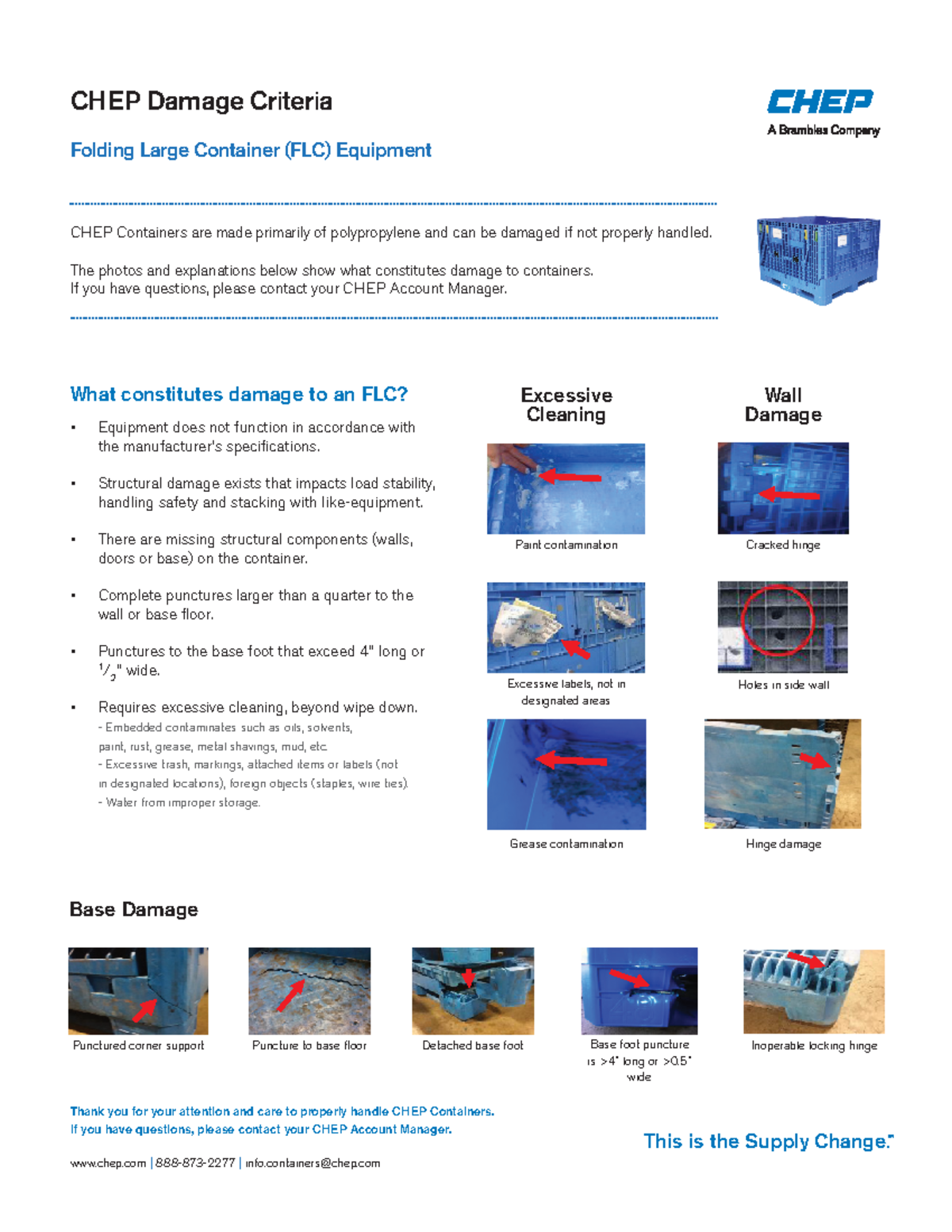

Quality Guidelines - Final - CHEP Damage Criteria Folding Large

Casestudy's | CHEP