Unlocking Industrial Excellence: The Walter Surface Technologies Legacy

In the vast and complex world of industrial manufacturing and metalworking, the pursuit of greatness is a continuous journey. It demands not only skill and dedication but also the right tools and solutions. While a name like "Walter Mendez" might evoke thoughts of a celebrated individual, in the context of industrial prowess and groundbreaking innovation, "Walter" takes on a different, equally impactful meaning. It points directly to Walter Surface Technologies, a global leader relentlessly focused on supplying the solutions to help the metalworking industry achieve greatness.

For decades, Walter Surface Technologies has been synonymous with pioneering advancements in industrial tools, abrasives, and comprehensive services. Their unwavering commitment to innovation, safety, and sustainability has positioned them as an indispensable partner for professionals striving for superior results. This article delves deep into the ethos, offerings, and impact of Walter Surface Technologies, exploring how their dedication to working better translates into tangible benefits for industries worldwide.

Table of Contents

- The Core Mission of Walter Surface Technologies: Forging Greatness in Metalworking

- A Comprehensive Arsenal: Industrial Tools, Abrasives, and Services

- Safety and Consistency: A Non-Negotiable Standard

- User-Centric Design: Enhancing Efficiency on the Shop Floor

- Versatility in Application: Tackling Diverse Metalworking Challenges

- The Pillars of Walter's Innovation: Research, Development, and Sustainability

- Why Professionals Choose Walter: A Synthesis of Quality and Trust

- Conclusion: Partnering for a Brighter Industrial Future

The Core Mission of Walter Surface Technologies: Forging Greatness in Metalworking

At its heart, Walter Surface Technologies operates with a singular, powerful mission: "Supplying the solutions to help the metalworking industry achieve greatness." This isn't just a tagline; it's the fundamental principle guiding every product development, every service offering, and every customer interaction. The pursuit of greatness in metalworking is multifaceted, encompassing not only the quality of the final product but also the efficiency of the process, the safety of the workers, and the sustainability of the operations. Walter understands these intricate demands and dedicates its resources to addressing them comprehensively. Their philosophy is built on delivering innovative, safe, and sustainable products designed to empower professionals to "work better." This holistic approach recognizes that true greatness is achieved when tools are not only high-performing but also contribute to a safer, more environmentally responsible workplace. By consistently pushing the boundaries of what's possible in industrial solutions, Walter Surface Technologies ensures that their partners in the metalworking industry are always equipped with the best, enabling them to tackle complex challenges with confidence and precision. This commitment to continuous improvement and user-centric innovation is a cornerstone of their long-standing success and reputation.A Comprehensive Arsenal: Industrial Tools, Abrasives, and Services

Walter Surface Technologies distinguishes itself by offering a complete ecosystem of "expert solutions for industrial tools, abrasives, and services." This integrated approach means that metalworking professionals don't just get individual products; they gain access to a cohesive system designed to optimize every stage of their operations. From initial material preparation to final finishing, Walter provides the essential components that ensure seamless workflow and superior outcomes. This breadth of offerings underscores their deep understanding of the diverse needs within the metalworking sector, from heavy fabrication shops to precision manufacturing facilities. The range of industrial tools provided by Walter is meticulously engineered to withstand the rigors of demanding environments, offering reliability and consistent performance. Complementing these tools, their extensive line of abrasives is designed for maximum efficiency and durability, a critical factor in reducing operational costs and improving productivity. Beyond physical products, Walter's commitment extends to comprehensive services, including technical support, training, and consultation, ensuring that users can leverage their solutions to their fullest potential. This all-encompassing portfolio solidifies Walter Surface Technologies' position as a true partner in industrial success.Precision and Performance: The Edge of Walter Abrasives

The core of many metalworking operations lies in the effectiveness of abrasives, and Walter Surface Technologies excels in this domain. "Our abrasives are engineered for durability, efficiency, and..." superior performance, setting a benchmark in the industry. They offer "a gama completa de abrasivos de alto desempenho concebidos para satisfazer as exigências dos profissionais metalúrgicos modernos." This means that whether the task involves heavy material removal, precise finishing, or surface preparation, Walter has a specialized abrasive solution tailored to the specific application. Their commitment to high-performance is evident in features designed to deliver consistent results. One of the standout characteristics of Walter's abrasive technology is its ability to maintain performance under load. As highlighted, "Rpm remains constant under load for a consistent and uniform finish every time." This is a critical advantage, as fluctuations in RPM can lead to uneven finishes, increased rework, and reduced productivity. By ensuring a steady rotational speed, Walter abrasives provide predictable and high-quality results, minimizing material waste and maximizing efficiency. This level of precision and consistency is what modern metalworking professionals demand to meet stringent quality standards and tight deadlines, making Walter abrasives a trusted choice for critical tasks.Cutting-Edge Innovation: The Walter Zip One and Beyond

Innovation is not just a buzzword for Walter Surface Technologies; it's ingrained in their product development philosophy. A prime example of this commitment to pushing boundaries is their cutting disc technology. The data highlights "O disco de corte mais fino da walter com 1/32'' foi concebido para um corte de máxima precisão." This ultra-thin design is a testament to advanced engineering, allowing for incredibly precise cuts with minimal material loss and heat distortion, crucial for delicate or high-tolerance applications. Such precision tools are vital for industries where accuracy directly impacts product integrity and performance. Further exemplifying their innovative spirit is the "Zip One" cutting disc. "Graças a uma tecnologia inovadora exclusiva da walter, o zip one não só é..." exceptionally fast and efficient, but also offers extended life and enhanced safety features. This exclusive technology represents a significant leap forward in abrasive performance, reducing cutting times and operator fatigue while ensuring a cleaner, smoother cut. The continuous development of such specialized products demonstrates Walter's dedication to solving real-world challenges faced by metalworking professionals, providing them with tools that are not just effective but also redefine industry standards for speed, accuracy, and overall operational excellence.Safety and Consistency: A Non-Negotiable Standard

In any industrial setting, safety is paramount, and Walter Surface Technologies places it at the forefront of their product design and manufacturing. The directive to "Choose walter for the safest and most consistent performance on the job" is more than just a recommendation; it's a reflection of their deep-seated commitment to worker well-being. Accidents in metalworking can be severe, making the reliability and safety features of tools and consumables absolutely critical. Walter engineers their products with robust safety mechanisms and materials that minimize risks, such as unexpected breakage, excessive vibration, or harmful dust exposure. Consistency, hand-in-hand with safety, is another hallmark of Walter's offerings. Consistent performance means predictable outcomes, which translates to fewer errors, less rework, and ultimately, a safer and more efficient workplace. When a tool or abrasive performs identically every time it's used, operators can develop muscle memory and trust in their equipment, reducing the likelihood of mistakes that could lead to injury. This reliability also contributes significantly to product quality and delivery schedules, reinforcing Walter's reputation as a dependable partner. Their rigorous quality control processes ensure that every product leaving their facilities meets the highest standards, providing peace of mind for professionals who rely on their tools daily.User-Centric Design: Enhancing Efficiency on the Shop Floor

Beyond raw performance and safety, Walter Surface Technologies understands that practical usability is key to maximizing productivity on the shop floor. Their commitment to user-centric design is evident in thoughtful features that simplify operations and reduce potential for error. A prime example is the use of "Color coded for easy identification in the shop." In a busy, often fast-paced industrial environment, quick and accurate identification of tools and consumables is crucial. Imagine a worker needing a specific abrasive for a particular task; a glance at a color-coded system allows for immediate selection, saving valuable time and preventing the use of incorrect materials. This seemingly simple feature has a profound impact on efficiency. It streamlines inventory management, reduces training time for new employees, and minimizes the risk of misapplication, which can lead to damaged workpieces or compromised safety. Walter's dedication to such practical design elements reflects their deep understanding of the daily challenges faced by metalworking professionals. By making their products intuitive and easy to use, Walter not only enhances operational flow but also contributes to a more organized and less stressful work environment, allowing skilled workers to focus on their craft rather than fumbling with tool identification.Versatility in Application: Tackling Diverse Metalworking Challenges

The metalworking industry is incredibly diverse, encompassing a wide array of materials, processes, and desired outcomes. Walter Surface Technologies designs its products with this versatility in mind, ensuring that their solutions are adaptable to numerous applications. While some products are "Most commonly used to remove paint, rust and corrosion or for light..." surface preparation, their extensive portfolio extends far beyond these basic tasks. This adaptability makes Walter a go-to provider for shops handling everything from heavy-duty fabrication to intricate finishing work. For instance, their abrasives and cutting tools are engineered to perform optimally on various metals, including stainless steel, aluminum, and high-strength alloys, each presenting unique challenges. Whether it's grinding welds, deburring edges, cleaning surfaces, or preparing materials for coating, Walter offers specialized solutions that deliver consistent, high-quality results. This comprehensive applicability means that professionals can rely on Walter for a broad spectrum of their needs, simplifying procurement and ensuring compatibility across different stages of a project. The ability to tackle diverse challenges with reliable, high-performance tools is a significant factor in why Walter Surface Technologies remains a preferred choice for professionals seeking efficiency and excellence.The Pillars of Walter's Innovation: Research, Development, and Sustainability

Innovation at Walter Surface Technologies is not a static concept; it's a dynamic, ongoing process driven by continuous research and development. This commitment ensures that their product lines are always at the cutting edge, incorporating the latest materials science and engineering advancements. Their R&D efforts are directly influenced by feedback from industry professionals and emerging market needs, allowing them to proactively develop solutions that address future challenges. This forward-thinking approach is crucial in an industry that constantly evolves with new materials and manufacturing techniques. Beyond performance, sustainability forms another critical pillar of Walter's innovation strategy. Recognizing the environmental impact of industrial processes, Walter is dedicated to developing products that are not only effective but also reduce waste, conserve energy, and minimize hazardous byproducts. This includes longer-lasting abrasives that require fewer replacements, products designed for lower energy consumption, and formulations that are safer for both the user and the environment. This commitment to sustainability aligns with global efforts towards greener industrial practices, positioning Walter Surface Technologies as a responsible and forward-thinking leader in the metalworking sector.Beyond the Product: Walter's Commitment to Service and Support

While their innovative tools and abrasives are central to their offering, Walter Surface Technologies understands that true partnership extends beyond just selling products. Their "expert solutions for industrial tools and services" encompass a robust support system designed to maximize customer success. This includes comprehensive training programs that educate users on the proper and most efficient use of Walter products, ensuring optimal performance and safety. Such training is invaluable for both seasoned professionals and new recruits, helping to bridge skill gaps and promote best practices. Furthermore, Walter provides exceptional technical support, with knowledgeable specialists available to troubleshoot issues, offer application advice, and help customers select the right tools for specific jobs. This level of personalized service ensures that users can always get the most out of their Walter products, minimizing downtime and maximizing productivity. By fostering strong relationships with their clients and offering ongoing support, Walter Surface Technologies positions itself not just as a supplier, but as a trusted advisor and partner, deeply invested in the success of the metalworking professionals they serve.Global Reach, Local Impact: Walter's Presence in the Industry

Walter Surface Technologies operates on a global scale, serving diverse markets and industries across continents. This extensive reach allows them to gather insights from various industrial environments, fueling their product development with a broad understanding of global challenges and demands. Despite their international presence, Walter maintains a strong focus on delivering local impact. This means understanding the specific regulations, environmental considerations, and unique operational needs of each region they serve. Their distribution networks and local support teams ensure that customers worldwide have timely access to Walter's innovative products and expert services. This blend of global expertise and local responsiveness enables Walter Surface Technologies to adapt its solutions to specific market requirements, ensuring relevance and effectiveness wherever their products are used. This strategic approach strengthens their position as a leading provider of industrial solutions, building trust and reliability within the global metalworking community.Why Professionals Choose Walter: A Synthesis of Quality and Trust

The choice of industrial tools and solutions is a critical decision for any metalworking professional or business. It impacts productivity, safety, cost-efficiency, and the quality of the final product. Time and again, professionals "Choose walter for the safest and most consistent performance on the job" because the brand represents a powerful synthesis of unwavering quality and profound trust. This trust is earned through decades of delivering on promises: products that perform as expected, tools that last, and solutions that genuinely make work better and safer. The consistent high performance of Walter products, from their precision cutting discs like the Zip One to their durable, high-efficiency abrasives, minimizes downtime and maximizes output. Their commitment to safety standards reduces workplace risks, protecting valuable human capital. Moreover, the dedication of Walter Surface Technologies to innovation ensures that professionals are always equipped with state-of-the-art solutions, keeping them competitive in a rapidly evolving industrial landscape. Ultimately, choosing Walter means investing in reliability, efficiency, and a partner dedicated to helping the metalworking industry achieve its full potential.Conclusion: Partnering for a Brighter Industrial Future

In summary, Walter Surface Technologies stands as a testament to what can be achieved when innovation, safety, and sustainability converge in the industrial sector. From supplying comprehensive solutions to help the metalworking industry achieve greatness, to providing expert solutions for industrial tools, abrasives, and services, their impact is undeniable. Their dedication to engineering abrasives for durability and efficiency, and developing cutting-edge products like the 1/32'' thin cutting disc and the Zip One with exclusive technology, ensures that professionals can achieve maximum precision and consistent, uniform finishes every time. The emphasis on safety, user-centric design through color coding, and versatile applications for tasks like removing paint, rust, and corrosion, further solidifies their position as a leader. Walter's commitment extends beyond products, embracing robust service and support, and maintaining a global presence with local impact. For any professional or business in the metalworking industry looking to enhance productivity, prioritize safety, and embrace sustainable practices, the choice is clear. We encourage you to explore our innovative products today and discover how Walter Surface Technologies can empower you to work better and achieve new levels of excellence. Share your experiences or questions in the comments below, and let's continue the conversation on industrial advancement.

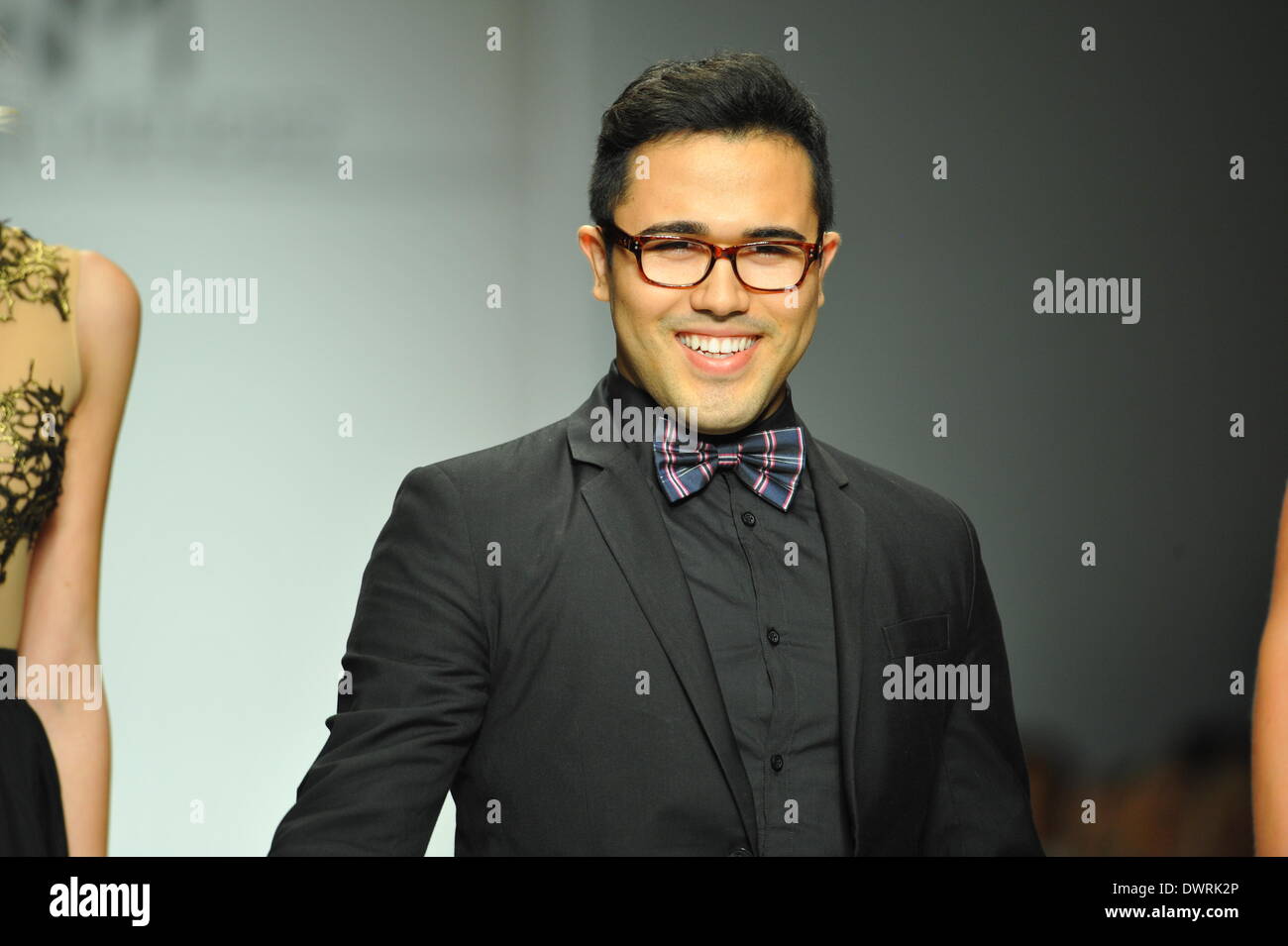

LOS ANGELES, CA - MARCH 10: Designer Walter Mendez and models walk

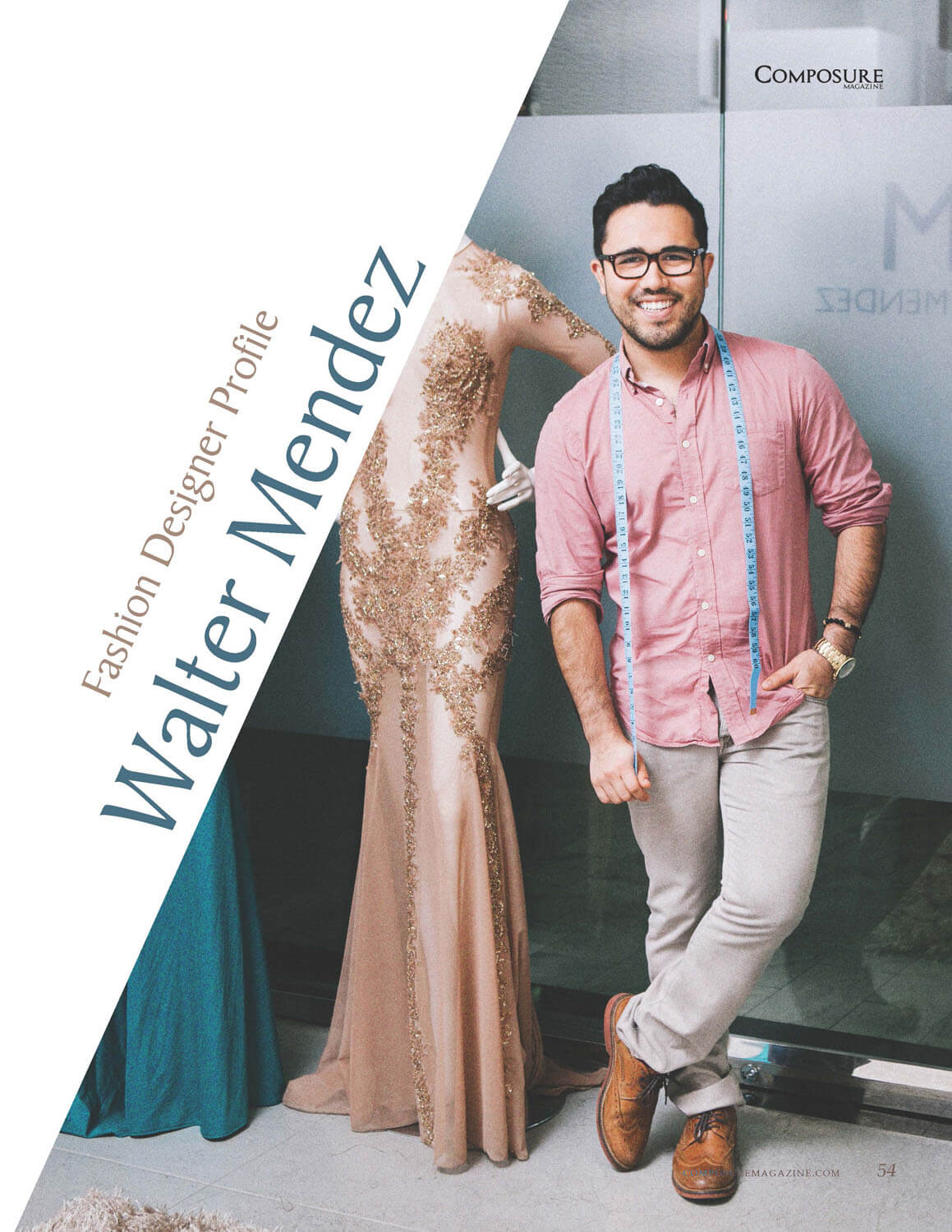

Fashion Designer Walter Mendez – Composure Magazine

Designer Walter Mendez Walks the Runway in a Walter Mendez Design at